Exploring the Market of China Titanium Nuts: A Comprehensive Guide

The global fastener market has witnessed significant advancements, particularly in the realm of titanium products. Among these, China titanium nuts stand out as an essential component in various industries. This article delves into the myriad aspects of titanium nuts produced in China, their advantages, manufacturing processes, applications, and the pivotal role played by leading manufacturers like titaniumbolts.com.

Why Titanium Nuts?

Titanium nuts offer a blend of superior properties that make them ideal for industrial applications. Here are some compelling reasons to opt for titanium over traditional materials:

- Lightweight: Titanium is significantly lighter than steel, making it perfect for applications where weight savings are critical.

- Corrosion Resistance: Titanium boasts exceptional resistance to corrosion, especially in harsh environments, which extends the life of fasteners.

- High Strength-to-Weight Ratio: This property ensures high durability and performance without the added weight, ideal for aerospace and automotive industries.

- Biocompatibility: Titanium is safe to use in medical implants and devices, making it a popular choice for the healthcare industry.

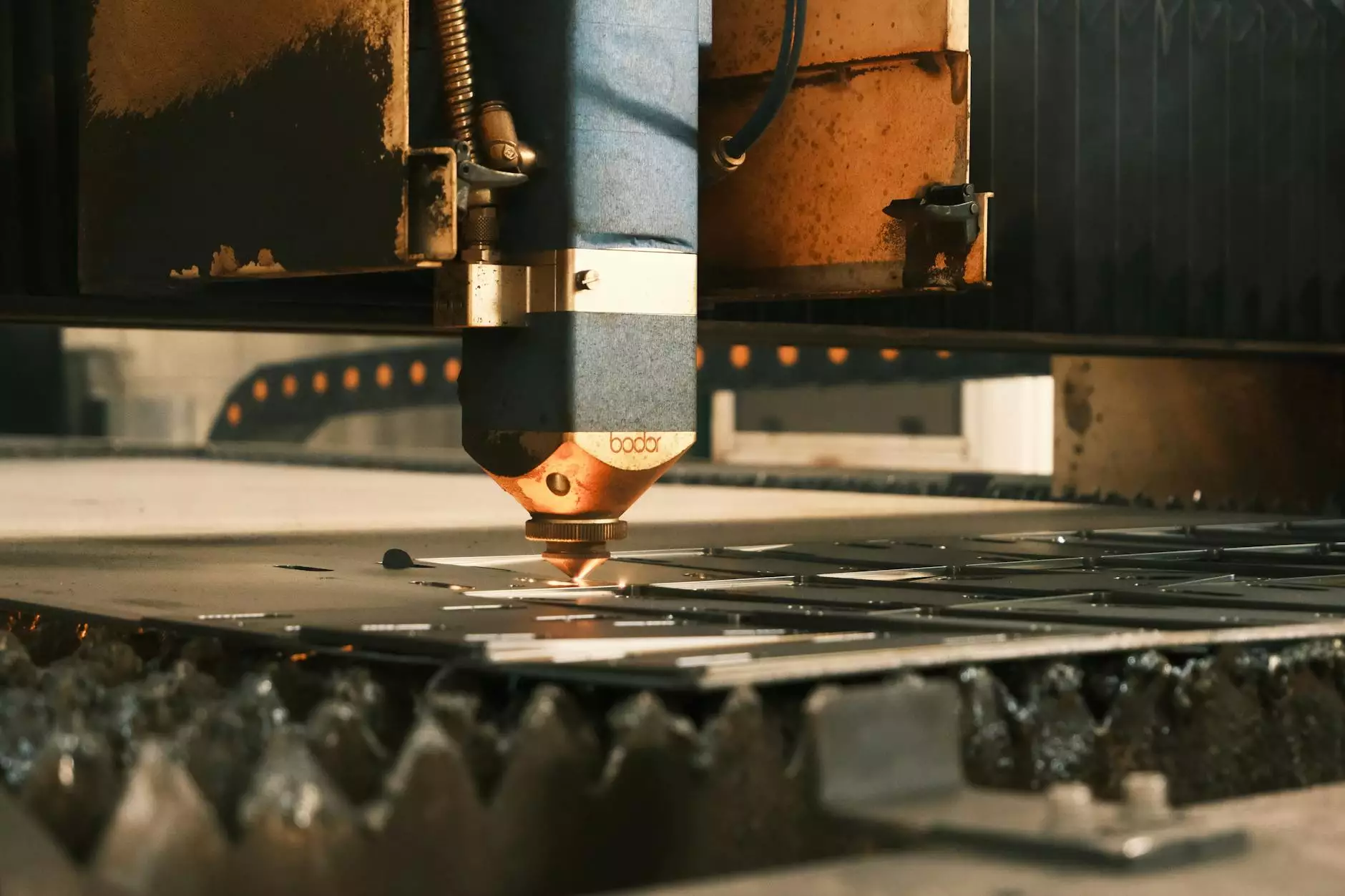

The Manufacturing Process of China Titanium Nuts

The production of China titanium nuts involves several meticulous processes to ensure high quality and reliability. Here’s a breakdown of the stages involved:

1. Material Sourcing

The journey of crafting high-quality titanium nuts starts with sourcing titanium ore. China is among the top producers of titanium, extracting minerals that meet international standards.

2. Melting and Alloying

Titanium is often alloyed with other metals to enhance its properties. This process requires specialized furnaces and techniques to achieve the desired composition.

3. Forming

Once the titanium is prepared, it undergoes forming processes. This could include:

- Forging: A technique that involves shaping the heated metal to create high-density components.

- Machining: Fine-tuning the dimensions and threading of the nuts to ensure precise fit and functionality.

4. Heat Treatment

After forming, titanium nuts may be subjected to heat treatment to enhance their strength and hardness.

5. Surface Finishing

To improve corrosion resistance and aesthetic appeal, various surface finishing techniques such as anodizing and passivation are employed.

Applications of China Titanium Nuts

The versatility of China titanium nuts enhances their applicability across a broad spectrum of industries:

Aerospace Industry

In aerospace manufacturing, weight and strength are paramount. Titanium nuts enable the construction of lightweight aircraft components that withstand extreme conditions.

Automotive Sector

In the automotive industry, the demand for durable yet lightweight materials is growing. Titanium nuts are often used in high-performance vehicles, particularly in motorsports.

Medical Applications

In the medical field, titanium's biocompatibility makes it ideal for surgical implants and devices, where titanium nuts are used to secure components.

Marine Applications

Given titanium's outstanding resistance to saltwater corrosion, it is extensively used in marine hardware and fasteners.

Comparing China Titanium Nuts with Alternatives

While there are various materials available for nuts and fasteners, titanium offers unique advantages that seldom match other metals, such as:

- Stainless Steel: While resistant to corrosion, stainless steel is heavier and less durable than titanium.

- Aluminum: Although lighter, aluminum lacks the same strength and can corrode more quickly.

Choosing the Right Manufacturer: What to Look For

When looking to source China titanium nuts, selecting the right manufacturer is crucial. Consider the following attributes:

Quality Control

Ensure that the manufacturer employs stringent quality control measures and adheres to international standards such as ISO certification.

Industry Experience

A manufacturer with years of experience will have refined processes and a deeper understanding of customer needs.

Customization Capabilities

Many applications require specific dimensions and types of titanium nuts. A competent manufacturer should be able to offer customization based on your requirements.

Customer Support

Reliable customer support is essential for addressing any queries or concerns during the purchase and after-sales stages.

Why Choose titaniumbolts.com for China Titanium Nuts?

At titaniumbolts.com, we pride ourselves on being a premier manufacturer of China titanium nuts. Here’s why partnering with us is beneficial:

- Wide Range of Products: We offer a comprehensive selection of titanium nuts to meet various industrial needs.

- Quality Assurance: Our products undergo rigorous testing to ensure they meet high standards of quality and performance.

- Expert Guidance: Our team is comprised of knowledgeable professionals ready to assist you in choosing the right products.

- Competitive Pricing: We strive to provide the best prices without compromising on quality.

Conclusion

China titanium nuts represent a remarkable innovation in the fastener market, showcasing attributes that ensure their growing popularity across multiple industries. As a reliable source, manufacturers like titaniumbolts.com are paving the way for advancements in technology and applications. By understanding the benefits and applications of titanium nuts, industries can leverage their potential to innovate and enhance their product offerings.

As you consider implementing titanium nuts into your projects, ensure you approach a reputable manufacturer who can meet your specifications and quality needs. The future of fasteners is here, and titanium is at the forefront.